The world’s starvation for power is rising at an unprecedented charge due to rising manufacturing and AI knowledge facilities. And our present electrical technology capabilities simply can’t deal with the demand. The scenario is so dire that the Worldwide Power Company predicts a tripling of solar panel installations in ten years, a surge that can require a close to doubling of the workforce. The U.S. photo voltaic business is at the moment putting in roughly 15,000 modules per hour which is laughable when business consultants are saying it wants to achieve a staggering 50,000 modules per hour by 2035 to maintain up with electrical energy demand.

The fact is that people can’t construct wind and photo voltaic farms quick sufficient—which is why utility and power technology firm AES has invented Maximo, an AI-powered robotic designed to double the pace of photo voltaic farm deployment. Constructing a photo voltaic farm requires shifting and putting in modules weighing greater than 60 kilos and measuring an unwieldy 6.5 x 3.25 toes every. It’s a tedious and probably harmful process. Maximo (nicknamed “Max”) is a medium-to-large, mild grey robotic that runs on two units of tracks that’s designed to make that operation a breeze.

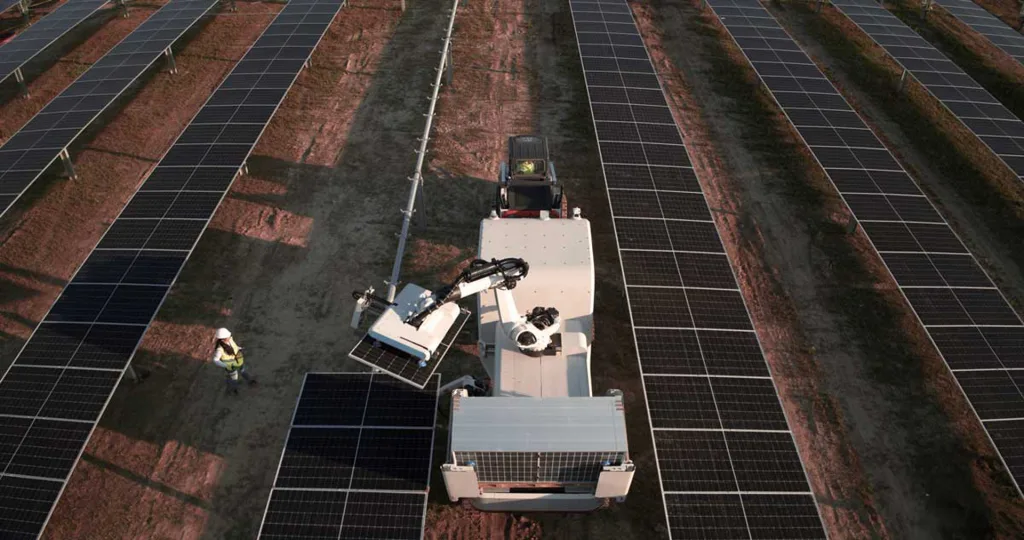

Its boxy chassis with curved corners has a central platform that holds the multi-jointed robotic arm that lifts and locations the photo voltaic panels. Small sensor modules dot the robotic, mapping its environment so it is aware of the place it’s always because it reaches into the cradle on its again that holds the panels. It’s a machine that appears like the long run, due to the design work of business and model design studio Fuseproject.

Launched final summer season, AES says Maximo has turn into the primary confirmed photo voltaic set up robotic available on the market. And whereas the corporate claims that Maximo isn’t meant to exchange human employees, it doesn’t actually need to. The photo voltaic business faces an excessive scarcity of expert labor, so it may’t sort out the sheer scale of the duty at hand with out utilizing machines like this good buggy with robotic eyes and arms.

The genesis of Maximo started two years in the past, as Yves Béhar, founder and principal designer of Fuseproject, instructed me throughout an interview. “We had a extremely fascinating preliminary dialogue about growing the capability of solar energy and making it extra environment friendly,” Béhar says. His expertise with robotics and electrical autos made the mission significantly interesting to him. “The mixture of car and robotics actually on the service of accelerating the set up and the capability of photo voltaic power was one thing that I used to be very, very all in favour of.”

Design ideas

The design course of targeted on a number of key ideas. Scalability was paramount, as was seamless integration into current workflows. Crucially, Maximo wanted to be “pleasant within the discipline,” a reliable good friend to the human employees it could collaborate with. “It’s not meant to exchange employees,” Béhar says. “It’s actually meant to enrich. It’s a instrument to speed up the transition to renewable power, decreasing the bodily calls for of getting to elevate panels [and accelerating the installation].”

Fuseproject wished to offer Maximo a definite identification aligned with AES’s model, whereas following very particular perform necessities to maximise effectivity within the actions and manufacturing cost-effectiveness. The design wanted to be scalable, too, because the imaginative and prescient was to have a military of bots masking deserts and plains with oceans of darkish silicon panels.

“Some of the vital standards was to visually combine all of the completely different elements,” Béhar explains, as Maximo is mainly a tank platform that should carry loads of eclectic parts. It has two mechanical arms for set up, a cradle that holds all of the panels that must get put in, the ability unit, and the AI module. Béhar tells me that these disparate components wanted to be tied below a single kind. His crew got here up with a metallic sine wave-shaped ribbon that expresses what the product does, whereas additionally offering important safety from the weather.

This steady kind turned out to be essentially the most visually important aspect of the robotic. Deise Yumi Asami, AES’s founder, says that “Fuseproject did an exceptional job on actually moving into the basics of what we wished to convey with Maximo.” The sine wave-like design included into Maximo’s form is a refined nod to the alternating present of electrical energy. “It’s actually tied to our core existence of power,” she explains.

Different design components, such because the aqua colour, references the AES brand. The precise shade was fastidiously chosen, Asami explains, as was the sunshine grey colour of the primary physique: “White on the development web site might be very difficult, so Fuseproject helped them tune the colour to a really mild colour of grey that will, you already know, be sufficient to satisfy our sort of like this sort of clear futuristic visuals of Max.”

The way it works

Maximo’s performance is as vital as its kind. The ribbon sine wave, for instance, additionally homes an built-in LED security system that indicators when human employees can strategy Max. That was one other core requirement from AES: The robotic wanted to be field-friendly, particularly when its quantity and energy is so unwieldy. “Max was actually developed to hold all of the heavy lifting, however not solely that, it needed to actually speed up the tempo during which we’re putting in photo voltaic panels,” Asami tells me.

Maximo strikes by itself, recognizing the terrain round it. An operator merely engages a protected swap simply in case one thing dangerous occurs after which Maximo takes over your complete operation due to a mix of laptop imaginative and prescient, synthetic intelligence, and a behavioral tree the corporate developed with Amazon AWS. “It is aware of the place to go. And it’ll resolve what’s the most effective path from path A to path B,” Asami says.

This enables Maximo to function within the dynamic, uncontrolled surroundings of a development web site, a key distinction from typical manufacturing unit robots which can be fastened in a single level and carry out repetitive duties at all times in the identical place. This out of doors operation offered essentially the most important technological problem, Asami says, requiring the event of strong AI and laptop imaginative and prescient methods able to dealing with glare and different visible points that occur below completely different climate situations and the altering place throughout completely different terrains.

Security was the third core requirement, not solely by the built-in LED mild system built-in within the ribbon—which turns pink, signaling to employees to take care of a protected distance when Max is working, even when it’s not shifting—however with ultrasonic sensors that detect if anybody enters the working zone, triggering a direct cease. “We’ve got an abundance of redundancy,” Asami factors out.

The cradle that holds the photo voltaic panels was a novel design problem. It looks like it’s the one module not completely built-in within the design. After I instructed Asami and Béhar, they acknowledged that there was no method round this, because it wanted to adapt to completely different panel sizes. “It must be frequently accessible too,” Asami says. “And mechanically talking, it adjusts to the completely different sizes of the photo voltaic modules.”

The adaptability of each facet of its design is essential to Maximo’s autonomous nature. When it arrives to the photo voltaic farm, a employee fastidiously hundreds a rack of photo voltaic panels into the ready cradle utilizing a forklift. With its cargo secured, Maximo embarks on its journey alongside the photo voltaic farm, counting on its refined laptop imaginative and prescient and mind to chart essentially the most environment friendly course and establish the place every panel ought to go.

As soon as it will get to the primary photo voltaic array assist construction, Maximo makes use of its arm to select up a panel from the cradle, easily rotating it and punctiliously inserting the panel onto the pre-installed mounting construction, known as the torque tube, earlier than securing it firmly in place. The mechanical set up is full after which, the method repeats. Panel after panel, Maximo strikes alongside the torque tube constructing the farm. The human operator solely acts as a supervisor, guaranteeing all the pieces runs easily, able to intervene if wanted. As soon as the cradle is empty, a employee reloads, and the cycle begins once more.

Shiny skies forward

Maximo has already put in almost 10 megawatts of photo voltaic and is projected to put in 100 MW in 2025. From these first experiences, plans are going to be placed on warp 9. AES claims it plans to deploy Maximo to assist construct as much as 5 gigawatts of its photo voltaic mission pipeline over the subsequent three years. Whereas AES isn’t disclosing particular manufacturing numbers, Asami says they’re significantly ramping up manufacturing of the robotic for his or her purchasers.

Asami’s ambition is to make Maximo a regular in photo voltaic farm development. With the growing labor shortages within the business and the rising demand for photo voltaic installations, evidently it’s going to be a “will need to have” moderately than a “may have.” The problem, she famous, is not only about constructing extra photo voltaic farms, but additionally about bringing them on-line shortly.

“Nearly all of the time that it’s spent on the location, it’s spent on the set up of photo voltaic modules,” she explains, making Maximo’s contribution to set up pace essential. “We do imagine that Max can have a huge impact,” she says. “And that’s why we see loads of rising opponents as nicely as a result of everybody understands the necessity within the business for one thing like Maximo.” Right here’s to seeing extra of those pleasant beasts with their glowing aqua and pink ribbons signaling the start of a brand new shiny photo voltaic world regardless of the dark stormy clouds now looming over us.