I wish to suppose I can study one thing about our readers from the checklist of most learn semiconductor articles. What I believe I’ve discovered from this yr’s checklist is that you’re as obsessed as I’m with packing increasingly computing energy into much less and fewer house. That’s good, as a result of it’s the principle objective of an enormous chunk of the business as nicely.

Not all of this checklist matches neatly into that mildew, however hey, who doesn’t love a millimeter-scale laser chip that may slice by way of metal?

1971 was a particular yr for plenty of causes—the first e-book was posted, the primary one-day international cricket match was performed, this reporter was born. It was additionally the primary time the semiconductor business offered greater than 1 trillion transistors. If TSMC executives’ predictions are right, there shall be 1 trillion transistors in just one GPU inside a decade. Simply how the foundry plans to ship such a technological feat was the topic of probably the most learn semiconductor story we posted this yr.

Susumu Noda

Slicing by way of metal and different feats of optical superheroism have, till very lately, been the reserve of enormous carbon dioxide lasers and equally cumbersome programs. However now, centimeter-scale semiconductors have joined the membership. Referred to as photonic crystal semiconductor lasers (PCSELs), the units benefit from a fancy array of fastidiously formed nanometer-scale holes contained in the semiconductor to steer extra vitality straight out of the laser. A PCSEL in-built Japan produced a steel-slicing beam that diverges simply 0.5 levels.

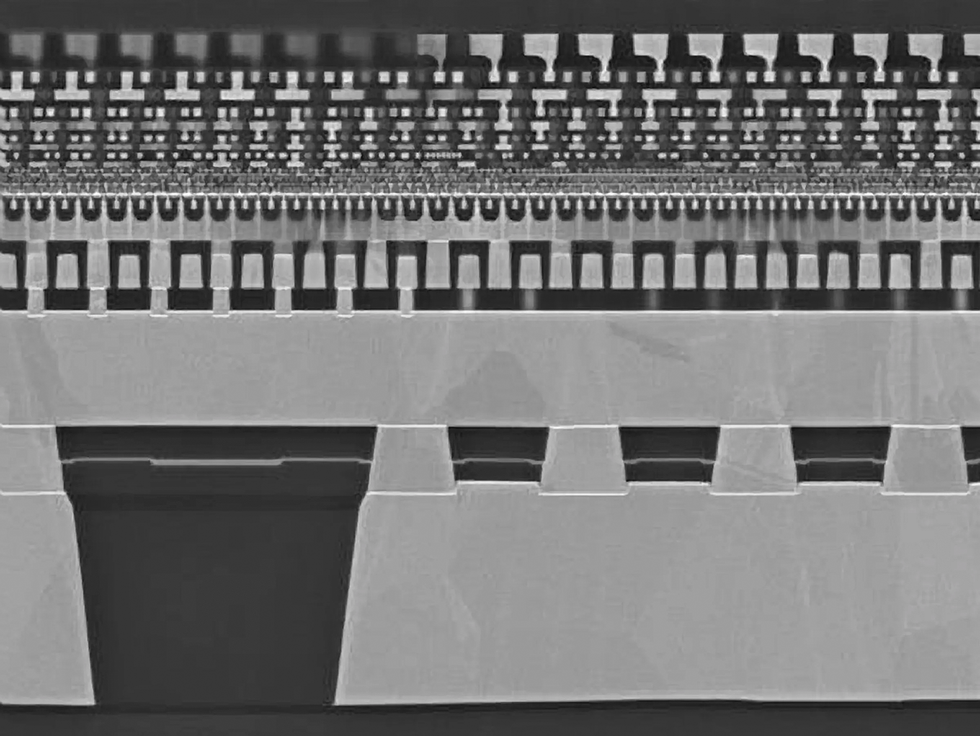

Intel had some huge ambitions initially of the yr. Issues are wanting loads much less rosy now. However, the predictions of this January 2024 difficulty article have come to pass. Intel is about to fabricate chips utilizing a mixture of two new applied sciences, nanosheet transistors and back side power delivery. Though the principle competitors, TSMC, is moving to nanosheets quickly, too, the foundry behemoth is leaving again aspect energy for later. However Intel’s plans didn’t fully survive contact with prospects and competitors. As a substitute of commercializing its first iteration of the combo, referred to as 20A, it’s skipping on to the following model, referred to as 18A.

Chris McKenney/Georgia Institute of Know-how

Graphene has lengthy been an fascinating materials for future electronics however a irritating one, too. Electrons zip by way of it at speeds silicon might solely want for, tempting researchers with the potential of terahertz transistors. Nevertheless it has no pure bandgap, and it’s confirmed actually tough to provide it one. However Georgia Tech researchers have given it one more go and provide you with a fairly easy strategy to make a semiconductor model atop a wafer of silicon carbide.

Intel

Intel’s foundry division is pinning its hopes on gaining foundry prospects for its 18A course of, which, as famous above, combines nanosheet transistors and again aspect energy supply. There haven’t been numerous particulars about what prospects plan to construct with this tech, however Intel executives did explain to IEEE Spectrum how they deliberate to make use of these applied sciences, and a few superior packaging too, in a server CPU codenamed Clearwater Forest.

David Plunkert

David Plunkert

Can anybody beat Nvidia? It’s the subtext of so many articles about AI {hardware}, that we thought we should ask it explicitly. The reply: A really strong possibly. All of it is determined by what you’re making an attempt to beat the corporate at.

iStock

In a yr when america inked a blitz of preliminary offers as a part of its $52-billion attempt to reinvigorate its chipmaking industry, our loyal readers had been far more thinking about India’s somewhat smaller moves. That authorities introduced a trio of offers, together with the nation’s first silicon CMOS fab. A key architect of India’s plans to spice up chip R&D explained it all to IEEE Spectrum later within the yr.

imec

imec

Chip packaging is without doubt one of the most necessary features of the continuation of Moore’s Legislation, enabling programs fabricated from many alternative silicon dies linked collectively as in the event that they had been one gigantic chip. And the most well liked factor in superior packaging is a expertise referred to as 3D hybrid bonding. (I do know this as a result of I sat in on at least 20 talks about it on the IEEE Electronic Components Technology Conference in Might 2024.) 3D hybrid bonding joins chips collectively in a vertical stack with connections so dense you would match thousands and thousands of them in a sq. millimeter.

KEK

KEK

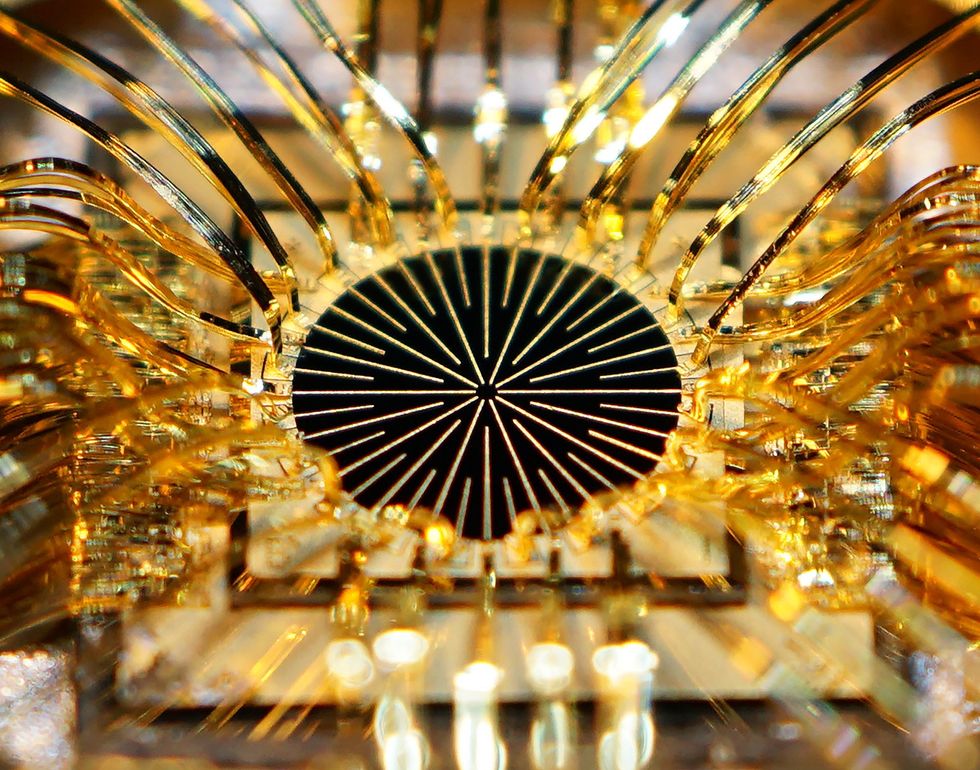

Simply whenever you thought the making of superior chips was already a bonkers course of, right here comes a touch that the longer term shall be much more bananas than the current. Excessive-ultraviolet lithography immediately depends on a Rube-Goldberg-esque process of zapping flying droplets of molten tin with kilowatt-class lasers to supply glowing balls of plasma. However future chipmaking will need brighter gentle than such a system might present. The reply, some say, is a gigantic particle accelerator that saves vitality by utilizing the high-energy physics model of regenerative braking.

Tesla

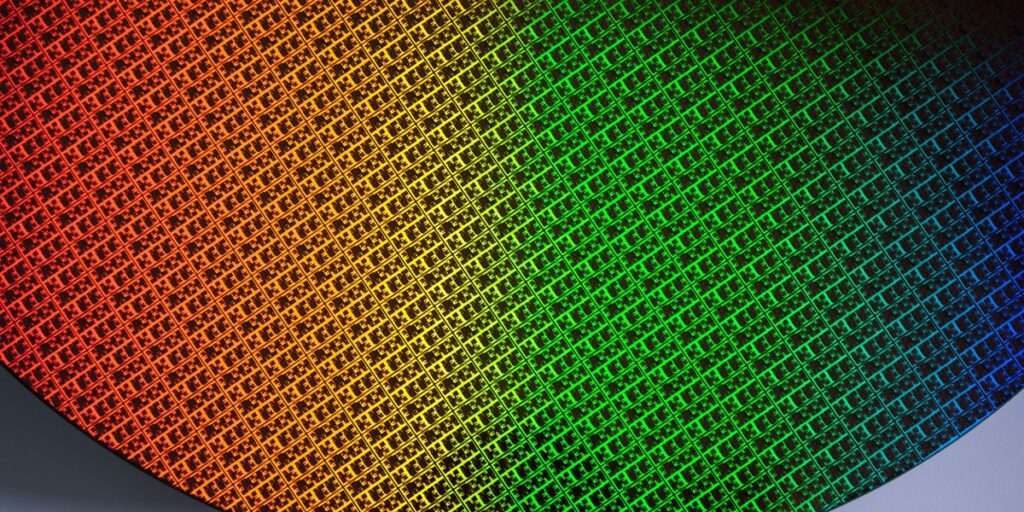

Like cowbell in a sure Seventies rock anthem, future computer systems want extra silicon. How a lot? How about a whole wafer’s full of it. Again in April, the world’s greatest foundry, TSMC, laid out its plans for superior packaging, and that future factors towards wafer-scale computer systems. TSMC has technically been making one for some time now for Cerebras, however what it’s planning to supply within the coming years shall be far more versatile and universally accessible. In 2027 the expertise might result in programs with 40 occasions as a lot computing energy as immediately’s

From Your Web site Articles

Associated Articles Across the Internet