This can be a sponsored article delivered to you by Freudenberg Sealing Technologies.

The growing deployment of collaborative robots (cobots) in out of doors environments presents vital engineering challenges, requiring extremely superior sealing options to make sure reliability and sturdiness. Not like industrial robots that function in managed indoor environments, out of doors cobots are uncovered to excessive climate circumstances that may compromise their mechanical integrity. Upkeep robots utilized in servicing wind generators, for instance, should endure intense temperature fluctuations, excessive humidity, extended UV radiation publicity, and highly effective wind hundreds. Equally, agricultural robots function in harsh circumstances the place they’re constantly uncovered to abrasive mud, chemically aggressive fertilizers and pesticides, and mechanical stresses from tough terrains.

To make sure these robotic techniques preserve long-term performance, sealing options should supply efficient safety towards environmental ingress, mechanical put on, corrosion, and chemical degradation. Outside robots should carry out flawlessly in temperature ranges spanning from scorching warmth to freezing chilly whereas withstanding fixed publicity to moisture, lubricants, solvents, and different contaminants. As well as, sealing techniques should be resilient to steady vibrations and mechanical shocks, that are inherent to robotic movement and might speed up materials fatigue over time.

Complete Technical Necessities for Robotic Sealing Options

The event of sealing options for out of doors robotics calls for an intricate steadiness of sturdiness, flexibility, and resistance to put on. Robotic joints, significantly these in high-mobility techniques, expertise multidirectional actions inside confined set up areas, making the number of acceptable sealing supplies and geometries essential. Conventional elastomeric O-rings, extensively utilized in industrial purposes, usually fail beneath such excessive circumstances. Publicity to excessive temperatures could cause thermal degradation, whereas steady mechanical stress accelerates fatigue, resulting in early seal failure. Chemical incompatibility with lubricants, fuels, and cleansing brokers additional contributes to materials degradation, shortening operational lifespans.

Friction-related put on is one other vital concern, particularly in robotic joints that function at excessive speeds. Extreme friction not solely generates warmth however may also have an effect on motion precision. In collaborative robotics, the place robots work alongside people, such inefficiencies pose security dangers by delaying response instances and lowering movement accuracy. Moreover, extended publicity to UV radiation could cause typical sealing supplies to turn into brittle and crack, additional compromising their efficiency.

Superior IPSR Expertise: Tailor-made for Cobots

To deal with these demanding circumstances, Freudenberg Sealing Applied sciences has developed a specialised sealing answer: Ingress Protection Seals for Robots (IPSR). Not like typical seals that depend on metallic springs for mechanical assist, the IPSR design options an modern Z-shaped geometry that dynamically adapts to the axial and radial actions typical in robotic joints.

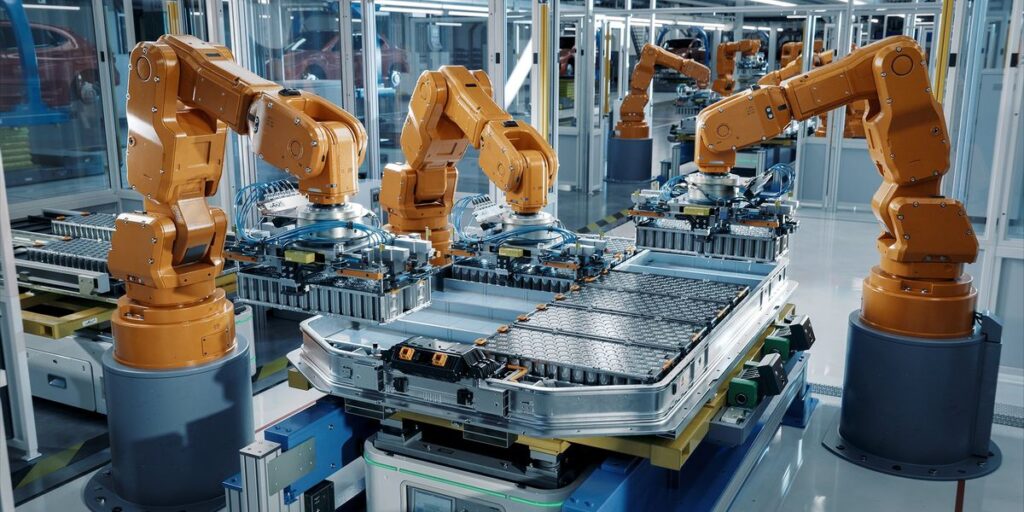

Quite a few seals are required in cobots and these are uncovered to excessive speeds and forces.Freudenberg Sealing Applied sciences

This distinctive structural design distributes mechanical hundreds extra effectively, considerably lowering friction and put on over time. Whereas conventional spring-supported seals are inclined to degrade resulting from mechanical fatigue, the IPSR configuration eliminates this limitation, making certain long-lasting efficiency. Moreover, the optimized contact strain reduces frictional forces in robotic joints, thereby minimizing warmth technology and lengthening element lifespans. This ends in decrease upkeep necessities, a vital think about purposes the place downtime can result in vital operational disruptions.

Optimized By means of Superior Simulation Methods

The event of IPSR know-how relied extensively on Finite Factor Evaluation (FEA) simulations to optimize seal geometries, materials choice, and floor textures earlier than bodily prototyping. These superior computational methods allowed engineers to foretell and improve seal conduct beneath real-world operational circumstances.

FEA simulations targeted on key efficiency elements corresponding to frictional forces, contact strain distribution, deformation beneath load, and long-term fatigue resistance. By iteratively refining the design primarily based on simulation information, Freudenberg engineers had been in a position to develop a sealing answer that balances minimal friction with most sturdiness.

Moreover, these simulations offered insights into how IPSR seals would carry out beneath excessive circumstances, together with publicity to humidity, fast temperature adjustments, and extended mechanical stress. This predictive strategy enabled early detection of potential failure factors, permitting for focused enhancements earlier than mass manufacturing. By lowering the necessity for intensive bodily testing, Freudenberg was in a position to speed up the event cycle whereas making certain high-performance reliability.

Materials Improvements: Superior Resistance and Longevity

The effectiveness of a sealing answer is essentially decided by its materials composition. Freudenberg makes use of superior elastomeric compounds, together with Fluoroprene XP and EPDM, each chosen for his or her distinctive chemical resistance, mechanical energy, and thermal stability.

Fluoroprene XP, specifically, affords superior resistance to aggressive chemical compounds, together with solvents, lubricants, fuels, and industrial cleansing brokers. Moreover, its resilience towards ozone and UV radiation makes it a great alternative for out of doors purposes the place steady publicity to daylight may in any other case result in materials degradation. EPDM, alternatively, supplies excellent flexibility at low temperatures and glorious growing older resistance, making it appropriate for purposes that require long-term sturdiness beneath fluctuating environmental circumstances.

To additional improve efficiency, Freudenberg applies specialised solid-film lubricant coatings to IPSR seals. These coatings considerably cut back friction and remove stick-slip results, making certain easy robotic movement and exact motion management. This friction administration not solely improves vitality effectivity but additionally enhances the general responsiveness of robotic techniques, a necessary think about high-precision automation.

Intensive Validation By means of Actual-World Testing

Whereas superior simulations present vital insights into seal conduct, empirical testing stays important for validating real-world efficiency. Freudenberg subjected IPSR seals to rigorous sturdiness assessments, together with extended publicity to moisture, mud, temperature biking, chemical immersion, and mechanical vibration.

All through these assessments, IPSR seals persistently achieved IP65 certification, demonstrating their means to successfully forestall environmental contaminants from compromising robotic elements. Actual-world deployment in upkeep robotics for wind generators and agricultural automation additional confirmed their reliability, with intensive put on evaluation exhibiting considerably prolonged operational lifetimes in comparison with conventional sealing applied sciences.

Security By means of Superior Friction Administration

In collaborative robotics, sealing efficiency performs a direct function in operational security. Extreme friction in robotic joints can delay emergency-stop responses and cut back movement precision, posing potential hazards in human-robot interplay. By incorporating low-friction coatings and optimized sealing geometries, Freudenberg ensures that robotic techniques reply quickly and precisely, enhancing office security and effectivity.

Tailor-made Sealing Options for Varied Robotic Techniques

Freudenberg Sealing Applied sciences supplies custom-made sealing options throughout a variety of robotic purposes, making certain optimum efficiency in numerous environments.

Automated Guided Autos (AGVs) function in industrial settings the place they’re uncovered to abrasive contaminants, mechanical vibrations, and chemical publicity. Freudenberg employs bolstered PTFE composites to boost sturdiness and defend inner elements.

Delta robots can carry out advanced actions at excessive velocity. This requires seals that meet the excessive dynamic and acceleration necessities.Freudenberg Sealing Applied sciences

Delta robots can carry out advanced actions at excessive velocity. This requires seals that meet the excessive dynamic and acceleration necessities.Freudenberg Sealing Applied sciences

Delta robots, generally utilized in meals processing, prescription drugs, and precision electronics, require FDA-compliant supplies that face up to rigorous cleansing procedures corresponding to Cleansing-In-Place (CIP) and Sterilization-In-Place (SIP). Freudenberg makes use of superior fluoropolymers that preserve structural integrity beneath aggressive sanitation processes.

Seals for Scara robots should have excessive chemical resistance, compressive energy and thermal resistance to perform reliably in a wide range of industrial environments.Freudenberg Sealing Applied sciences

Seals for Scara robots should have excessive chemical resistance, compressive energy and thermal resistance to perform reliably in a wide range of industrial environments.Freudenberg Sealing Applied sciences

SCARA robots profit from Freudenberg’s Modular Plastic Sealing Idea (MPSC), which integrates sealing, bearing assist, and vibration damping inside a compact, light-weight design. This innovation optimizes robotic weight distribution and extends element service life.

Six-axis robots utilized in automotive, aerospace, and electronics manufacturing require sealing options able to withstanding high-speed operations, mechanical stress, and chemical publicity. Freudenberg’s Premium Sine Seal (PSS), that includes bolstered PTFE liners and specialised elastomer compounds, ensures most sturdiness and minimal friction losses.

Steady Innovation for Future Robotic Functions

Freudenberg Sealing Applied sciences stays on the forefront of innovation, constantly creating new supplies, sealing designs, and validation strategies to handle evolving challenges in robotics. By means of strategic buyer collaborations, cutting-edge materials science, and state-of-the-art simulation applied sciences, Freudenberg ensures that its sealing options present unparalleled reliability, effectivity, and security throughout all robotic platforms.