This sponsored article is delivered to you by NYU Tandon School of Engineering.

In a major development for the sphere of drug supply, researchers have developed a brand new approach that addresses a persistent problem: scalable manufacturing of nanoparticles and microparticles. This innovation, led by

Nathalie M. Pinkerton, Assistant Professor of Chemical and Biomolecular Engineering on the NYU Tandon Faculty of Engineering, guarantees to bridge the hole between lab-scale drug supply analysis and large-scale pharmaceutical manufacturing.

The breakthrough, often known as Sequential NanoPrecipitation (SNaP), builds on present nano-precipitation methods to supply improved management and scalability, important components in guaranteeing that drug supply applied sciences attain sufferers effectively and successfully. This system allows scientists to

manufacture drug-carrying particles that maintain their structural and chemical integrity from lab settings to mass production—an important step towards bringing novel therapies to market.

Utilizing 3D Printing to Overcome a Problem in Drug Supply

Nanoparticles and microparticles maintain large promise for focused drug supply, permitting exact transport of medicines on to illness websites whereas minimizing unintended effects. Nevertheless, producing these particles persistently at scale has been a significant barrier in translating promising analysis into viable therapies. As Pinkerton explains, “One of many greatest boundaries to translating many of those exact medicines is the manufacturing. With SNaP, we’re addressing that problem head-on.”

Pinkerton is an Assistant Professor of Chemical and Biomolecular Engineering at NYU Tandon.NYU Tandon Faculty of Engineering

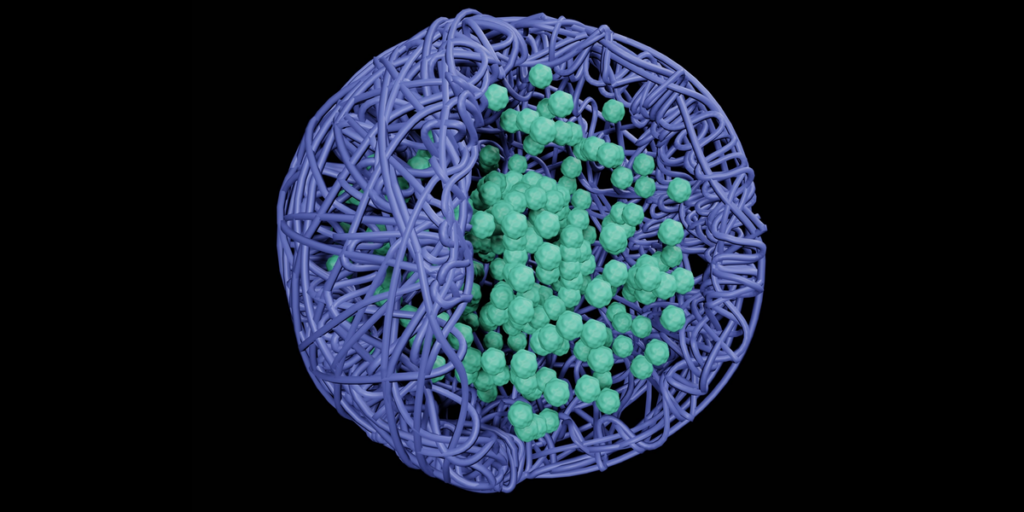

Conventional strategies like Flash Nano-Precipitation (FNP) have been profitable in creating some forms of nanoparticles, however they usually wrestle to supply bigger particles, that are important for sure supply routes corresponding to inhalable supply. FNP creates polymeric core–shell nanoparticles (NPs) between 50 to 400 nanometers in dimension. The method includes mixing drug molecules and block-copolymers (particular molecules that assist type the particles) in a solvent, which is then quickly blended with water utilizing particular mixers. These mixers create tiny, managed environments the place the particles can type rapidly and evenly.

Regardless of its success, FNP has some limitations: it will probably’t create secure particles bigger than 400 nm, the utmost drug content material is about 70 %, the output is low, and it will probably solely work with very hydrophobic (water-repelling) molecules. These points come up as a result of the particle core formation and particle stabilization occur concurrently in FNP. The brand new SNaP course of overcomes these limitations by separating the core formation and stabilization steps.

Within the SNaP course of, there are two mixing steps. First, the core elements are blended with water to start out forming the particle core. Then, a stabilizing agent is added to cease the core progress and stabilize the particles. This second step should occur rapidly, lower than a number of milliseconds after step one, to regulate the particle dimension and forestall aggregation. Present SNaP setups join two specialised mixers in sequence, controlling the delay time between steps. Nevertheless, these setups face challenges, together with excessive prices and difficulties in reaching brief delay occasions wanted for small particle formation.

A brand new strategy utilizing 3D printing has solved many of those challenges. Advances in 3D printing know-how now enable the creation of exact, slender channels wanted for these mixers. The brand new design eliminates the necessity for exterior tubing between steps, permitting for shorter delay occasions and stopping leaks. The modern stacked mixer design combines two mixers right into a single setup, making the method extra environment friendly and user-friendly.

“One of many greatest boundaries to translating many of those exact medicines is the manufacturing. With SNaP, we’re addressing that problem head-on.”

—Nathalie M. Pinkerton, NYU Tandon

Utilizing this new SNaP mixer design, researchers have efficiently created a variety of nanoparticles and microparticles loaded with rubrene (a fluorescent dye) and cinnarizine (a weakly hydrophobic drug used to deal with nausea and vomiting). That is the primary time small nanoparticles below 200 nm and microparticles have been made utilizing SNaP. The brand new setup additionally demonstrated the important significance of the delay time between the 2 mixing steps in particle dimension management. This management over the delay time allows researchers to entry a bigger vary of particle sizes. Moreover, the profitable encapsulation of each hydrophobic and weakly hydrophobic medication in nanoparticles and microparticles with SNaP was achieved for the primary time by Pinkerton’s crew.

Democratizing Entry to Chopping-Edge Methods

The SNaP course of isn’t solely modern but in addition presents a singular practicality that democratizes entry to this know-how. “We share the design of our mixers, and we display that they are often manufactured utilizing 3D printing,” Pinkerton says. “This strategy permits tutorial labs and even small-scale trade gamers to experiment with these methods with out investing in expensive gear.”

A stacked mixer schematic, with an enter stage for syringe connections (prime), which connects instantly to the primary mixing stage (center). The primary mixing stage is interchangeable, with both a 2-inlet or a 4-inlet mixer choice relying on the specified particle dimension regime (dotted antisolvent streams solely current within the 4-inlet mixer). This stage additionally comprises pass-through for streams used within the second mixing step. All of the streams combine within the second mixing stage (backside) and exit the gadget.

A stacked mixer schematic, with an enter stage for syringe connections (prime), which connects instantly to the primary mixing stage (center). The primary mixing stage is interchangeable, with both a 2-inlet or a 4-inlet mixer choice relying on the specified particle dimension regime (dotted antisolvent streams solely current within the 4-inlet mixer). This stage additionally comprises pass-through for streams used within the second mixing step. All of the streams combine within the second mixing stage (backside) and exit the gadget.

The accessibility of SNaP know-how might speed up advances throughout the drug supply subject, empowering extra researchers and corporations to make the most of nanoparticles and microparticles in creating new therapies.

The SNaP mission exemplifies a profitable cross-disciplinary effort. Pinkerton highlighted the crew’s range, which included specialists in mechanical and course of engineering in addition to chemical engineering. “It was actually an interdisciplinary mission,” she famous, declaring that contributions from all crew members—from undergraduate college students to postdoctoral researchers—had been instrumental in bringing the know-how to life.

Past this breakthrough, Pinkerton envisions SNaP as a part of her broader mission to develop common drug supply techniques, which might finally rework healthcare by permitting for versatile, scalable, and customizable drug supply options.

From Trade to Academia: A Ardour for Innovation

Earlier than arriving at NYU Tandon, Pinkerton spent three years in Pfizer’s Oncology Analysis Unit, the place she developed novel nano-medicines for the remedy of stable tumors. The expertise, she says, was invaluable. “Working in trade provides you a real-world perspective on what is possible,” she factors out. “The aim is to conduct translational analysis, that means that it ‘interprets’ from the lab bench to the affected person’s bedside.”

Pinkerton — who earned a B.S. in Chemical Engineering from the Massachusetts Institute of Know-how (2008) and a doctoral diploma in Chemical and Organic Engineering from Princeton College — was drawn to NYU Tandon, partly, due to the chance to collaborate with researchers throughout the NYU ecosystem, with whom she hopes to develop new nanomaterials that can be utilized for managed drug supply and different bio-applications.

She additionally got here to academia due to a love of educating. At Pfizer, she realized her need to mentor college students and pursue modern, interdisciplinary analysis. “The scholars right here need to be engineers; they need to make a change on the earth,” she mirrored.

Her crew on the Pinkerton Analysis Group focuses on creating responsive smooth supplies for bio-applications starting from managed drug supply, to vaccines to medical imaging. Taking an interdisciplinary strategy, they use instruments from chemical and supplies engineering, nanotechnology, chemistry and biology to create smooth supplies by way of scalable artificial processes. They give attention to understanding how course of parameters management the ultimate materials properties, and in flip, how the fabric behaves in organic techniques — the last word aim being a common drug supply platform that improves well being outcomes throughout illnesses and issues.

Her SNaP know-how represents a promising new path within the quest to scale drug supply options successfully. By controlling meeting processes with millisecond precision, this technique opens the door to creating more and more complicated particle architectures, offering a scalable strategy for future medical advances.

For the sphere of drug supply, the longer term is shiny as SNaP paves the best way towards an period of extra accessible, adaptable, and scalable options.